Article - Automotive Gearbox & Differential Parts

7 Nov 2017

Author - Gabby Candelli Automotive Data Manager

Services

31 Oct 2017

To partner our customers to achieve optimum plant reliability through the application of knowledge and technologies which deliver the highest level of service and results.

Vibration Analysis

31 Oct 2017

This is the predominant technology employed in condition monitoring to determine the condition of various mechanical components and hence be able to make a prediction on service life expectancy and urgency of repairs.

Training

31 Oct 2017

Through a continuous commitment to quality BSC strives to provide solutions for industry.

Stop Leak

31 Oct 2017

Air leaks are one of the biggest contributors to needless costs in any industrial plant/facility.

Specialist Installation Services

31 Oct 2017

Did you know that only 10% of bearings reach their design service life in the real world!

Predictive Maintenance

31 Oct 2017

For Asset Optimization.

Predictive maintenance PdM aims to find measures of machinery condition and use them to prevent breakdowns. Establishing trends allow accurate pinpointing of machinery problems and their severity. Increasing up time on machines is the primary aim, while reduced likelihood of secondary failures and less unnecessary maintenance are additional benefits.

Oil Analysis

31 Oct 2017

Oil analysis is a cost effective method for determining the condition of existing lubricants and hence, predicting remaining service life.

Mechanical Equipment Refurbishment Service

31 Oct 2017

BSC Engineering Services can provide bearing refurbishment services which could save you thousands compared to a new bearing, particularly if lead times are longer than required for large or specialized bearings.

Laser Alignment

31 Oct 2017

Mis-alignment in mechanical systems such as motor/pump assemblies is a major factor in increased wear and premature failures.

Balancing

31 Oct 2017

Unbalanced fans, pumps and rotors place undue stresses and additional loads on bearings, motors and couplings substantially reducing component service life, and potentially causing a catastrophic failure which can damage surrounding equipment and harm employees.

Consulting and Design

31 Oct 2017

BSC can provide engineering consulting services for upgrades and new equipment designs.

Energy Audit Service

31 Oct 2017

Energy consumption can be reduced up to 40% by analysing inefficient and poorly designed drives and adopting good drive design practices.

Infrared Thermography

31 Oct 2017

Using a camera designed to capture heat energy in the infra-red (IR) spectrum, abnormal temperature conditions in machines and electrical devices can be identified.

Timber & Paper Case Studies

11 Dec 2017

Sugar Industry Case Studies

11 Dec 2017

Other Case Studies

11 Dec 2017

Case Studies

7 Nov 2017

Mining Industry Case Studies

11 Dec 2017

Food & Beverage Case Studies

7 Nov 2017

Agricultural Case Studies

8 Feb 2018

BSC service the Transport Industry

12 Nov 2017

BSC has extensive experience in the transport industry across Australia. Our experience enables us to understand the special needs that relate specifically to your business and production processes, including;

Energy conservation

Product longevity

Harsh operating conditions

Working with BSC is a partnership that goes a lot further than just delivering the right part. Utilising our Engineering Services expertise we keep production lines moving through proactive help to avoid breakdowns, minimising costly downtime and improving your production efficiency.

We provide constant monitoring and continuous reduction of working capital.

BSC service the Timber & Paper Industry

12 Nov 2017

The timber industry is a diverse, multi-faceted industry. From felling trees to grinding and milling, loads, accuracies and working conditions vary and manufacturers must have products that excel in these varying environments.

BSC has extensive experience in the timber and paper industry enabling us to understand the special needs that relate specifically to your business and production processes.

BSC service the Packaging Industry

12 Nov 2017

BSC has extensive experience of working with numerous companies in the packaging industry across Australia. Our experience enables us to understand the special needs that relate specifically to your business and production processes.

Vibration Analysis

12 Nov 2017

This is the predominant technology employed in condition monitoring to determine the condition of various mechanical components and hence be able to make a prediction on service life expectancy and urgency of repairs.

It is a non-invasive technique which collects vibration data from machines under normal operating conditions. Vibration readings are typically taken at bearing locations following accepted industry practices and conventions.

This raw waveform data is then transformed into a spectral format and analyzed with proprietary software which allows analysis to take place.

Training

12 Nov 2017

Through a continuous commitment to quality BSC strives to provide solutions for industry.

Utilising our technical expertise we have developed comprehensive product training programs. For the engineer seeking assistance with selecting the appropriate materials or components, a distributor who wants to provide the best available advice and products to your customers, or a maintenance person interested in getting the maximum uptime and performance from your equipment, BSC can help.

Our training program can be tailored to your audience and delivered at your site. Where no standard training program exists to address your needs, we have the experts who can tailor a program just for you.

Stop Leak

12 Nov 2017

Air leaks are one of the biggest contributors to needless costs in any industrial plant/facility.

A leak is a costly drain on overall operating costs. State-of-the-art ultrasonic equipment is used to identify air leaks.

The “Stop Leak” Process is the first step in continuous improvement. Every identifiable leak, including fittings, valves, flanges and hoses are tagged with a number, its location, severity and cost.

Specialist Installation Services

12 Nov 2017

Did you know that only 10% of bearings reach their design service life in the real world!

A major source of failure is incorrect handling and fitting procedures. BSC Engineering Services can provide supervision and assistance with bearing fitting, v-belt tensioning, coupling and roll alignments, and other installation work. Ensuring components are installed correctly to manufacturers specifications provides your site with the best opportunity of maximizing service life and reducing unnecessary down time and production losses.

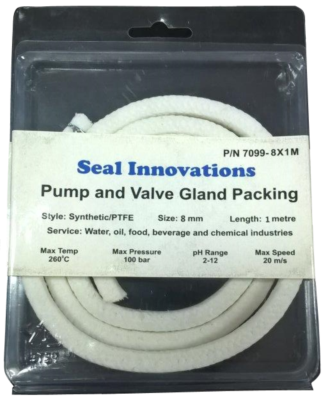

Seal Innovations General Purpose Gland Packaging

13 November, 2017